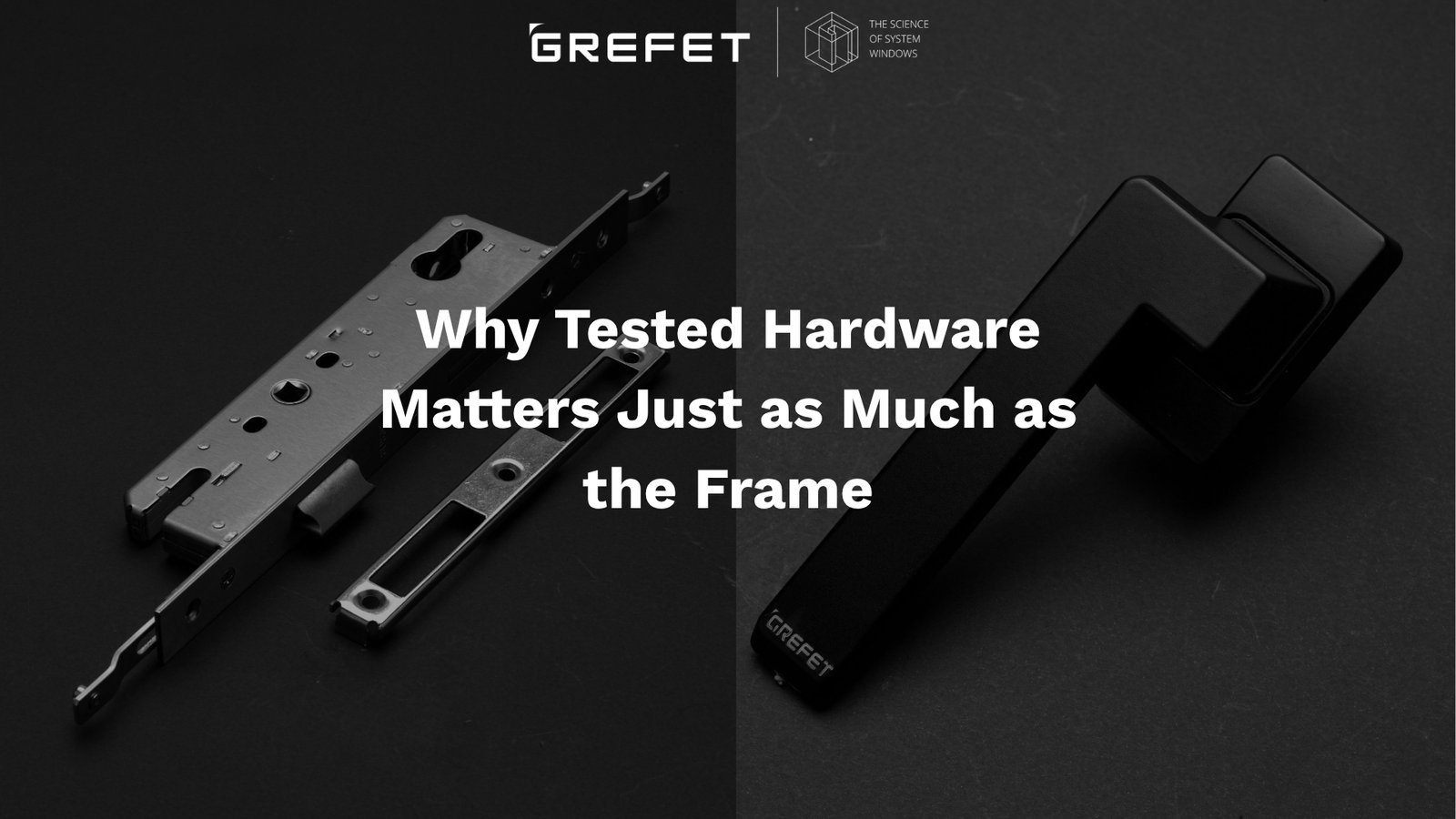

When choosing aluminium windows or doors, most of the attention tends to go to the frame. Is it slim? Is it strong? Does it look good? But here’s the thing, tested hardware matters just as much as the frame. In fact, even the best aluminium profile can underperform or fail if paired with substandard hardware. At GREFET, we don’t treat hardware as an afterthought. It’s a critical component of every system we design and supply.

Let’s break down why tested hardware is essential, what to look for, and how GREFET ensures every element of a window system, inside and out, is up to the mark.

Performance Under Pressure

The purpose of a window or door system is to operate reliably over decades. That reliability isn’t just about the aluminium, it’s about how the hinges carry the load, how the locks secure the sash, and how sliders glide with precision over time. Every piece of hardware affects performance.

Tested hardware, especially when validated under international standards like prEN 1935:2013 for hinges or EN 1191 for operational cycles, guarantees the product has passed rigorous assessments for mechanical strength, fatigue resistance, corrosion, and safety. If your project is in a coastal city like Mumbai or a dusty, dry zone like Rajasthan, this kind of assurance becomes non-negotiable.

Safety & Security

Here’s what a lot of end-users don’t realise: window and door safety starts at the hardware level. A well-reinforced aluminium frame is meaningless if the locking system can be pried open with a screwdriver.

At GREFET, we use multi-point locking systems, tamper-proof handles, and tested hinges that resist break-ins. All of these components are sourced from certified vendors and tested in our in-house and third-party labs for:

- Load-bearing capacity

- Resistance to forced entry

- Endurance across thousands of open-close cycles

Whether you’re building a high-end villa or a mid-rise commercial block, security should never be compromised.

Smooth Operation Over Time

Nothing ruins the premium feel of aluminium windows faster than sticky sliders, sagging sashes, or creaky hinges. It doesn’t matter how sleek the frame is — if the hardware fails, the experience does too.

This is where GREFET’s commitment to tested hardware pays off. Our systems undergo cycle testing, often 20,000+ open-close actions, before getting certified. We ensure:

- Sliders remain smooth even after years of use

- Casement hinges don’t sag, even with heavy glass

- Friction stays optimal, reducing wear and tear on both the frame and hardware

In simpler words, they just keep working. Quietly, efficiently, without drama.

Compatibility & System Integrity

Not all hardware works with every system. Many fabricators make the mistake of mixing third-party handles or locks with aluminium profiles not designed for them. This causes leaks, poor sealing, and premature wear.

At GREFET, our window and door systems are engineered as complete assemblies, not just profile kits. We pair our aluminium frames with matching, tested hardware to ensure:

- Air and water tightness stay intact

- Drainage functions properly

- Maintenance is minimal

This ensures the performance claimed in brochures matches what’s delivered on-site.

Why GREFET Invests in Tested Hardware

We see tested hardware not as a cost, but as an investment, in durability, safety, and peace of mind. Our systems are made to handle real-life use, not just showroom displays. Every hinge, lock, and roller goes through:

- Mechanical cycle testing

- Salt spray testing for corrosion resistance

- Load tests to check long-term reliability

And because GREFET is a system brand, not just a supplier of aluminium profiles, we stand by the full package, frame, glass, gasket, hardware, and performance.

It’s Not Just What You See, It’s What Holds It Together

The next time you evaluate a window system, don’t stop at the sightlines or surface finish. Ask about the hardware. Is it tested? Is it certified? Or is it made to last?

Because tested hardware matters just as much as the frame, and at GREFET, we never separate the two.